Brands, Health, Mattresses

Botanicore Botanical Latex

Bedrooms & More has specialized in latex mattress & bedding for over 30 years.

Botanicore™ botanical latex is simply the cleanest. That’s why we choose to source and manufacture our own latex. In this blog we cover why 45th Street Bedding (our sister brand), only chooses to use 100% botanical latex sourced straight from the rubber tree.

Botanicore™ is the purest natural latex available

It’s comfortable, consistent, environmentally responsible, all botanical (straight from the tree, not synthetic or blended with chemical compounds), long lasting, and problem free. Compared to other latex, including “certified organic latex”, Botanicore™ is visibly and structurally better. We have an in-store display of our Botanicore™ latex alongside natural latex samples made with other processes, and customers can observe the differences. That’s why we use Botanicore™ as the core of our 45th Street Bedding mattresses.

Rubber Tree sap collection

Selection of Latex (Rubber) Sap

Aging latex between 30 and 50 days after tapping from the tree makes for the best finished product. Sap can’t be too ‘young’ or too ‘old’ to when making a superior product. Stirring for a minimum of 8 hours each day ages latex properly without premature hardening.

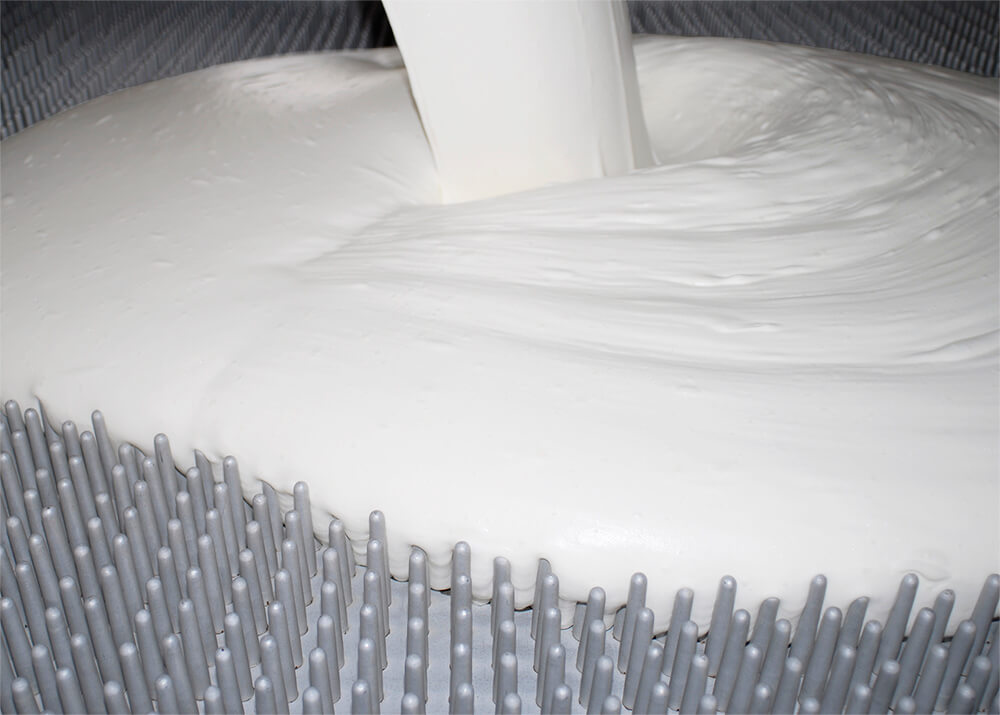

The next step after aging is whipping soap and air into the latex. Once prepared, latex goes into a mold that resembles a waffle iron. Workers hand trowel the whipped latex evenly across the surface. Rotation and vertical baking until the core is solid makes for the greatest uniformity.

Production of our latex occurs near the plantations where the rubber sap is harvested. This prevents the need for additional chemicals. Adding chemicals to stabilize the latex during transport to distant facilities is a common practice by many other companies.

We partner with a second generation company to make our Botanicore™. Together, we are well-versed in how to properly manufacture mattress cores and have developed a relationship with our manufacturing plant.

Manufacturing Process: Rubber Tree to Mattress Core

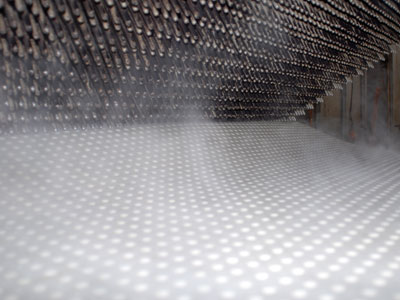

Our Botanicore™ latex is manufactured in a vertical oven using a controlled heating process. This ensures that the final product is consistent, with no surface bubbling and/or other visual or structural inconsistencies. This process makes the latex core feel equal on each side with uniform density throughout.

Botanical Latex pour

Consistency to the Core

Botanicore™ contains no fillers or patches. There are no air pockets that can cause soft spots and it has proven and measurable conformity across the bed. Testing for consistency is integral to the process. We practice stringent specifications to ensure conformity and we log every core. We track each mattresses from the beginning of their production process until they land in a consumer’s home. Both sides of the natural latex core have the same feel, making it ideal for two-sided mattresses, which is all we sell, by the way.

Heat Press

Durable Design

You know that feeling when you sit down on the side of your bed and worry you might slide right off? We’ve designed Botanicore™ so that it doesn’t happen. Every mattress core has built in PURE Edge Support™.

Latex Core Testing

Solid Core Construction

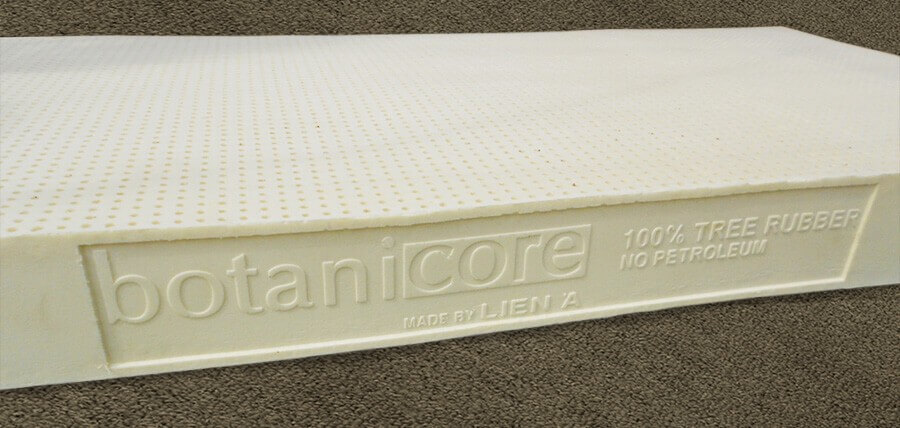

When we say ‘100% natural latex’ or ‘all botanical latex’, we mean NO synthetic or blended latex. Our Botanicore™ is exclusively made from rubber trees. Every mattress utilizes a one-piece mold for that specific size. This allows for consistent density throughout, and for the built-in “pure edge support” that is an integral part of our design. In order to build the larger sizes, many brands will glue smaller pieces together resulting in uneven support side to side, as well as unwanted ridges caused by the use of glue.

Core Longevity

100% botanical latex is the longest lasting support system for mattresses. Synthetic latex (soy, poly, memory foam, gel foams), which are all rubberized plastics, or blended latex (what is often called ‘natural’ latex) foams, all break down; Botanicore™ won’t.

Botanicore™ Latex Core

Visual quality & consistency you can count on

Put Botanicore™ latex next to any other latex core and the difference is obvious. You’ll notice the consistency and finished edge. Then you’ll see how our material stretches while other latex foams simply tear.

A botanical latex core is the purest, safest, and healthiest latex you’ll find on the market. Botanicore™ is simply the highest quality all-natural latex available for use in our two-sided mattresses.

Visit us

Visit our Bedrooms & More locations and test sleep a botanical latex mattress, you’ll be amazed by 2-sided, uniform comfort.

Let’s Talk. We’re Listening.

Have you owned a Botanicore™ botanical Latex mattress? Tell us about your experience.